Designed for customized parts processing

Sand casting offers the advantage of shape flexibility due to the mold’s excellent plasticity, allowing metals to be cast with sand cores to form detailed and complex shapes. Additionally, sand molds help absorb gases and residues during the casting process, reducing the likelihood of pores and defects in the final product. This method is also relatively cost-effective and allows for reusable molds, making it ideal for batch production with reduced mold costs.

Advantages of Sand Casting:

⚡ Low-Cost Batch Production: Suitable for medium to low-volume production, enabling rapid manufacturing of identical parts within a short period.

⚡ Casting Flexibility: Capable of producing both large and small castings with consistent quality.

Investment casting (lost wax casting) is often used for producing complex, three-dimensional metal objects, commonly applied in the mass production of stainless steel components. In this process, a wax model is first created and coated with a high-temperature refractory material to form a mold. The mold is then heated, causing the wax to melt and leave a cavity, into which molten stainless steel is poured to form the casting.

Scope of Services

We create realistic product models or prototypes based on customer-provided requirements and drawings. These models accurately replicate the intended design, allowing for detailed evaluation and testing before moving to mass production.

We manufacture jigs to enhance production accuracy, molds for mass production, and fixtures to hold semi-finished products during the manufacturing process. These tools ensure precision, efficiency, and consistency throughout production, improving overall manufacturing quality.

Based on processing drawings or customer samples, we use CNC machines or EDM (Electrical Discharge Machines) to create and shape parts, modifying them to meet the client’s specific requirements. This ensures precision and customization throughout the production process.

We provide just-in-time production based on customer needs, minimizing storage and inventory costs. This approach ensures efficient production while reducing overhead related to warehousing and excess stock.

Basic Processing Materials

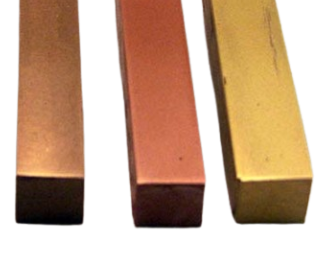

Metals

Copper is renowned for its excellent electrical conductivity and thermal properties, making it widely used in electrical components. Bronze (an alloy of copper and tin) offers high corrosion resistance and fatigue strength, commonly used in bearings, bushings, and marine hardware. Brass (an alloy of copper and zinc) is durable with a low friction coefficient, making it ideal for producing high-precision components and tools.

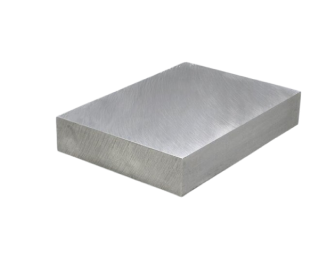

Aluminum is lightweight yet strong, easy to machine, and corrosion-resistant, making it commonly used in aerospace and automotive industries for lightweight components.

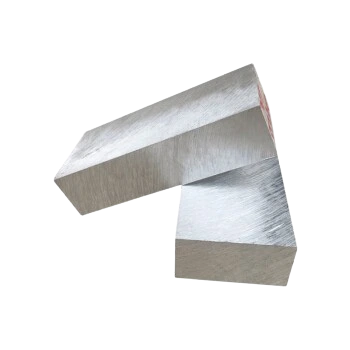

Stainless steel is renowned for its corrosion resistance and is commonly used in medical devices, robotics, and automated manufacturing equipment.

Material Properties and Surface Options

We provide a wide range of materials, including metals, plastics, and composites.

We offer superior surface finishes that enhance part durability and aesthetics for applications requiring smooth or textured surfaces.

Applied Industries

IDMockup offers top-notch manufacturing capabilities, whether for rapid prototyping or custom production orders. Our self-owned factories and satellite factories are equipped to efficiently produce complex, high-quality parts.

👉 For more about our latest news, technology and equipment, please follow our official Facebook, X (Twitter) and official blog!